TECHNOLOGY

of AlNiCo cast magnet manufacture

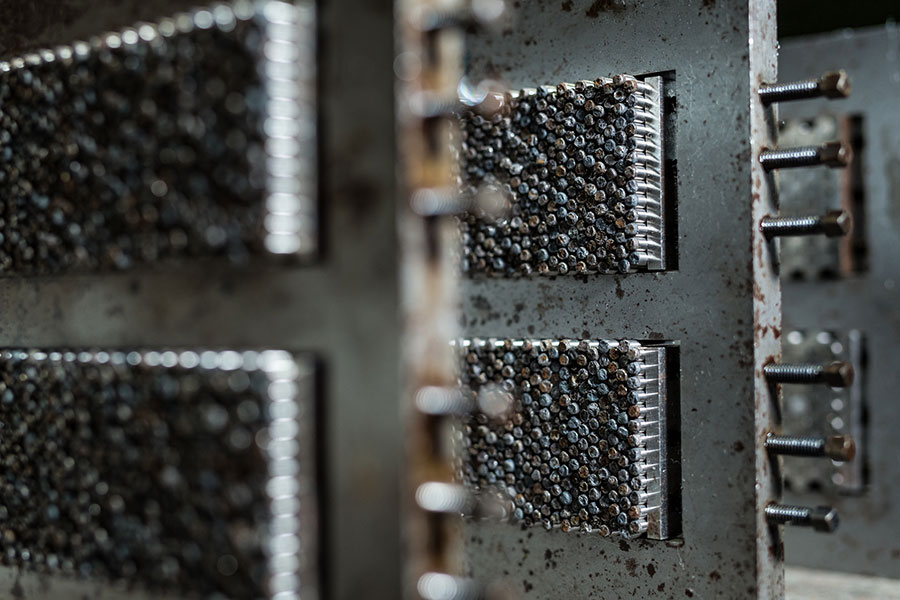

Moulding shop / foundry

- Shaping the moulds, stacking

- Melting, tapping, casting, analysing

- Removing the casting, after cooling separation from recyclable material

- Cleaning and weighing of the recyclable material

- Storing the material for subsequent utilization

- Weighing the casting and making it available for the next processing stage

- Creating batch documents for further processing stages (batch cards)

Thermomagnetic treatment division

- Deburring the casting

- Loading into the annealing box for heat treatment

- Homogenization annealing

- Magnetic field treatment

- Tempering

- Demagnetization

Grinding shop

- Centreless external cylindrical grinding for cylindrical products

- Clamping into stentering frame

- Two- or multi-sided (cuboid) surface grinding treatment on rotary table surface grinding machine

Testing laboratory

- Chemical, geometrical and magnetic inspections

- Calculation of melting charge

Division for sorting, magnetization, shipping

- Visual inspection as per customer specifications

- If required: magnetization / skin packaging

- Bulk packaging for non-magnetic material